The DHIS2 Annual Conference takes place from 15-18 June 2026! Learn more

Strengthening end-to-end Supply Chain Management with DHIS2 and Open mSupply in Comoros

Comoros leverages DHIS2 integrated with Open mSupply to digitize stock management across public health facilities, improving supply chain resilience and decision-making.

Comoros is a small island nation in the Indian Ocean with a population of just under one million people, yet it faces significant logistical challenges in delivering health commodities due to its geography and limited infrastructure. Spread across three main islands and dozens of smaller islets, the country struggled with supply chain data silos, paper-based stock records, and lacked visibility into stockouts and distribution inefficiencies.

To address these gaps, the Ministry of Health, in partnership with HISP Rwanda, the DHIS2 for Logistics team at the HISP Centre at the University of Oslo (HISP UiO), and the mSupply Foundation, launched the eLMIS (logistics management information system) project in 2024, with funding from the World Bank. This hybrid logistics system combines DHIS2 at the facility level and Open mSupply at central and regional warehouses to enable real-time stock data and reduce supply chain waste. What was once a paper based reporting system is now digitized and provides visibility at all levels of the supply chain for paid medical products, as well as digitizing the order workflow.

From paper records to digital stock data

Before this implementation, health facilities recorded stock transactions by hand, and it often took weeks to compile national reports. Warehouse inventories were managed separately, leaving the Ministry unable to follow stock movements or anticipate shortages. Meanwhile, almost 99 percent of public health facilities already used DHIS2 for health service reporting, but not for reporting data on health commodities.

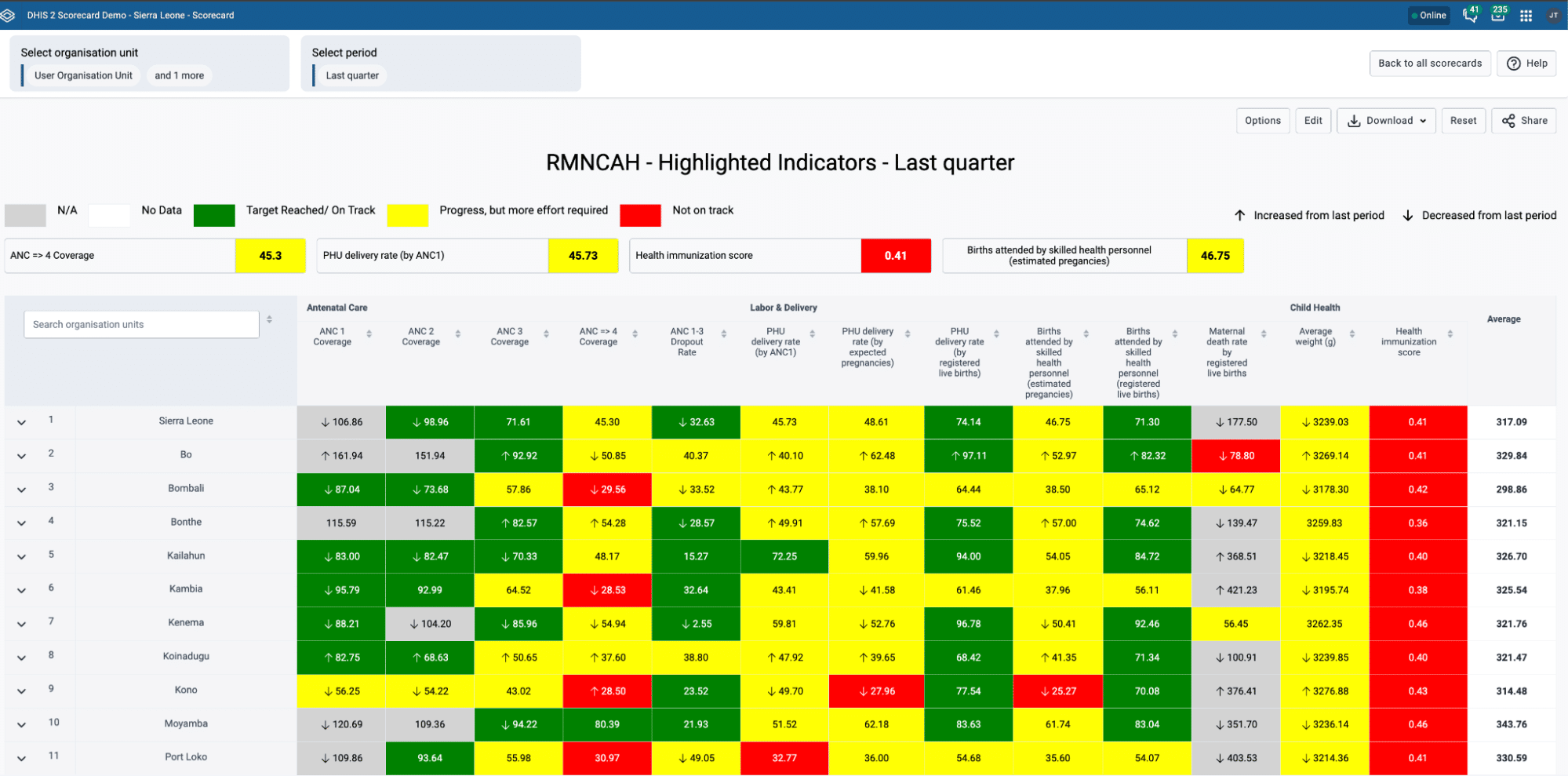

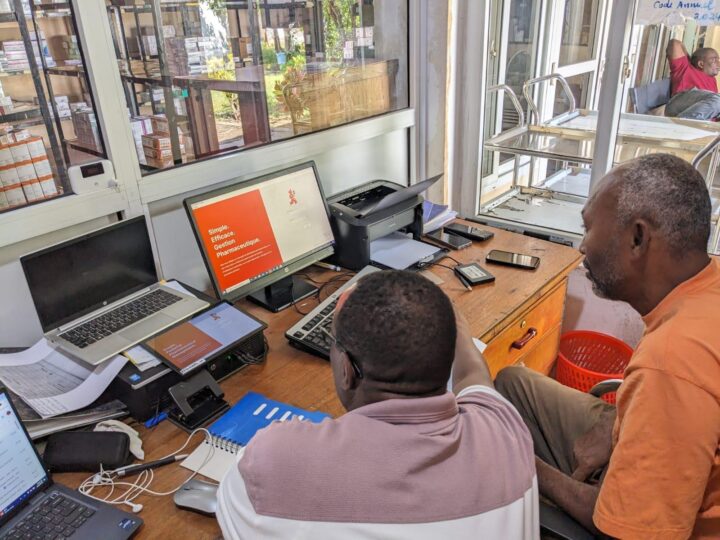

Under the eLMIS project, health facility staff now record stock transactions directly in DHIS2 using the Real-Time Stock Management tool on Android mobile devices, while some facilities facing severe connectivity issues record monthly stock reports. Within just over 3 months of the system going live, nearly 30,000 transactions were completed and the number of facilities using RTS had reached 58 of 74 sites, or 78% of all facilities. Central and regional warehouses manage transactional inventory in Open mSupply. These DHIS2 and Open mSupply systems have been integrated by using DHIS2 extensibility features and tooling developed in the Open mSupply system, ensuring that data is shared seamlessly between both systems. This approach maintains a familiar reporting interface for health workers while digitizing warehouse operations, supporting ordering from facility (DHIS2) to warehouse (mSupply) and automating national reporting.

Local Ministry staff in Comoros are being trained to maintain DHIS2 configurations and dashboards, supported by HISP Rwanda, which provides technical assistance in system design, integration, and governance. Together, the partners are laying the foundation for national digital supply chain management that is both efficient and sustainable.

Tracking and using stock data for better decisions

Early results show clear gains in stock visibility. Health managers can now track shortages and overstock situations across facilities, identify geographic trends, and coordinate redistribution before critical gaps occur.

“The central medical store, actually, they are able to see the stock levels through the health centers, which was not existing before,” said Amine Ahmed Chamsi, a data scientist with the Comoros Ministry of Health. With this new system, the Ministry is “able to have visibility, end to end, from the medical products, from the lowest to the national level, so that we can avoid stock-outs.”

The integrated DHIS2-Open mSupply system now provides a unified view of logistics data from the central warehouse to individual facilities. While full performance metrics—such as reductions in stockouts and wastage—are still being collected, initial dashboards already highlight recurring shortages in island facilities, enabling the Ministry to adjust buffer stocks and delivery schedules if needed.

The Ministry is also beginning to connect logistics information with service indicators such as immunization coverage to better understand how supply availability affects health outcomes.

Enabling sustainability and system maturity

Sustainability is central to the Comoros design. By embedding logistics reporting within the national DHIS2 platform, which is already familiar to most health workers, the project avoids parallel systems and reinforces national ownership. The hybrid DHIS2-Open mSupply setup keeps facility reporting simple while managing warehouse complexity through Open mSupply–an approach that will be refined for use in other countries through the newly launched collaboration between HISP UiO and the mSupply Foundation.

HISP Rwanda leads DHIS2 customization and capacity building in Comoros, with ongoing handover of maintenance to Ministry colleagues. A steering committee and technical working group oversee implementation and ensure alignment with national health policies.

Challenges remain, including connectivity limitations on remote islands, synchronization delays in mobile apps, and a shortage of local technical expertise. The project is following a phased rollout, starting in key regions, to ensure stability as the system expands nationwide.

As implementation continues, the eLMIS is already helping Comoros improve visibility, coordination, and efficiency across its health supply chain—laying the foundation for a more resilient, data-driven system in the years ahead.