The DHIS2 Annual Conference takes place from 15-18 June 2026! Learn more

Using DHIS2 for Improved Cold Chain Equipment Monitoring and Management in Malawi

Malawi’s Ministry of Health used DHIS2 Tracker to register and manage its vaccine cold chain equipment, cataloging more than 300 pieces of equipment across 20 districts in only four weeks, and reducing inventory reporting time from years to minutes.

Cold chain equipment and vaccine stock data—two cornerstones of effective nationwide immunization programs—have represented key challenges for Malawi in recent years. Storms have damaged existing cold chain equipment and weakened the electric grid and transportation infrastructure in some areas, and disease outbreaks have further strained cold storage capacity. Additionally, cold chain equipment records in Malawi have commonly used a patchwork of non-standardized, web-based spreadsheets, email messages, and paper forms, which complicate data consolidation and analysis, as well as equipment allocation and maintenance.

Because of its previous success using DHIS2 for Covid-19 surveillance and response, Malawi’s health officials decided in 2022 to use the platform to modernize its vaccine cold chain equipment (CCE) management and monitoring. Staff from the Expanded Programme on Immunization (EPI) and the Digital Health Division–with support from UNICEF Malawi–designed and tested a new CCE system in DHIS2, and trained technicians to register and manage CCE items in Tracker. Technicians then registered and tracked more than 300 total pieces of equipment across 20 districts in the span of four total weeks. The improved CCE monitoring in these districts has supported informed resource allocation and maintenance planning as technicians can now view inventory, equipment status, and transactions on their DHIS2 dashboards in real time. Inventory data that once took five years to generate is now available within five minutes.

“The cold chain equipment management system has helped us to access the cold chain inventory, know every transaction that has happened, and help in planning the next due CCE service.” Lucius Future Chisale, cold chain technical assistant, Central East Zone

Identifying workflows and key metadata inform Tracker configuration and CCE technician training

Management of cold chain equipment in Malawi has been paper based, with some standalone electronic spreadsheet files, until very recently, according to Blessings Kamanga, a product manager with the Ministry’s Digital Health Division. He said some cold chain managers made early progress by moving to web-based spreadsheets, but that approach presented challenges as well. “For example, if you want to know stock levels, or maybe operational status, that was very difficult because it means you have to consolidate those individual files and make sure that you can do the analysis on your own in Excel. So, that was a gap,” he explained. Previously, national EPI team members would need to travel to each of the CCE facilities to generate a thorough inventory—a process that typically occurred once every five years—and now that same information can be accessed within five minutes. “Now, within five minutes, we can log in to the system and pull out the data, update the functionality status, or sync data back to the server,” Kamanga said.

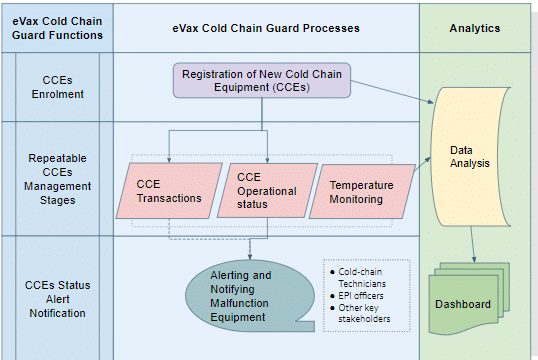

An important first step to digitizing and standardizing its workflows for cold chain equipment monitoring and management, the Digital Health Division conducted a thorough review of the hard-copy forms and the various electronic spreadsheets in use. They worked to establish exactly which data items were being collected, and pinpointed the management stages of the existing workflow, which included equipment transactions, operational status, temperature monitoring, and more. “Once you’ve registered the equipment, you may need to dispatch it to some other facility, or you may need to carry out planned or corrective maintenance,” Kamanga said of the CCE processes. “We also need to know if the equipment has triggered an alarm to indicate the temperature has gone beyond the threshold, which would require some action to be taken.”

Based on these requirements, the national team designed a process for registering and managing the equipment, and two DHIS2 technicians from the Digital Health Division developed a Tracker program, now called “eVax Cold Chain Guard,” within the national electronic vaccination (eVax) module on Malawi’s One Health Surveillance Platform. After the EPI team completed testing, staff from the Digital Health Division and EPI provided training for cold chain technicians from two targeted districts—Lilongwe and Ntchisi. They gave a brief orientation, demonstrating how to register, monitor, and manage CCE items in the system, and distributed labels with unique identifier quick response (QR) codes to support faster data entry and equipment tracking.

National team provides oversight and support for district-level technicians for successful implementation

Following their orientation with the eVax Cold Chain Guard system in March 2024, CCE technicians from the two districts began registering equipment in their facilities—attaching the QR code labels and entering the corresponding data on mobile devices. In only three weeks, the technicians in these two districts were able to register 200 pieces of equipment in 105 facilities. A week later, those first technicians provided mentoring to technicians in 18 additional districts, who then registered another 100 pieces of equipment in one week, for a combined result of 300 items registered in a total of four weeks.

Throughout the equipment registration process in the first two districts, the national team used a group chat on a popular text messaging app for live troubleshooting and other kinds of implementation assistance, and members of the Digital Health Division and EPI traveled to many of the CCE facilities to monitor progress and resolve any ongoing issues with equipment registration. In one case, the team discovered that some technicians using their own mobile devices for data entry were not able to upload data because of problems with a required field, and took quick action to resolve this by editing the data collection form.

In addition to the use of personal devices for data entry, the team encountered challenges with internet connectivity at some of the more remote facilities. “We used the DHIS2 Android Capture app extensively to make sure the data is collected in those areas,” Kamanga said. While it was not possible to get real-time data in these areas due to lack of connectivity, using this app meant that users could capture the data electronically on site, then upload it to the server as soon as they had network coverage again.

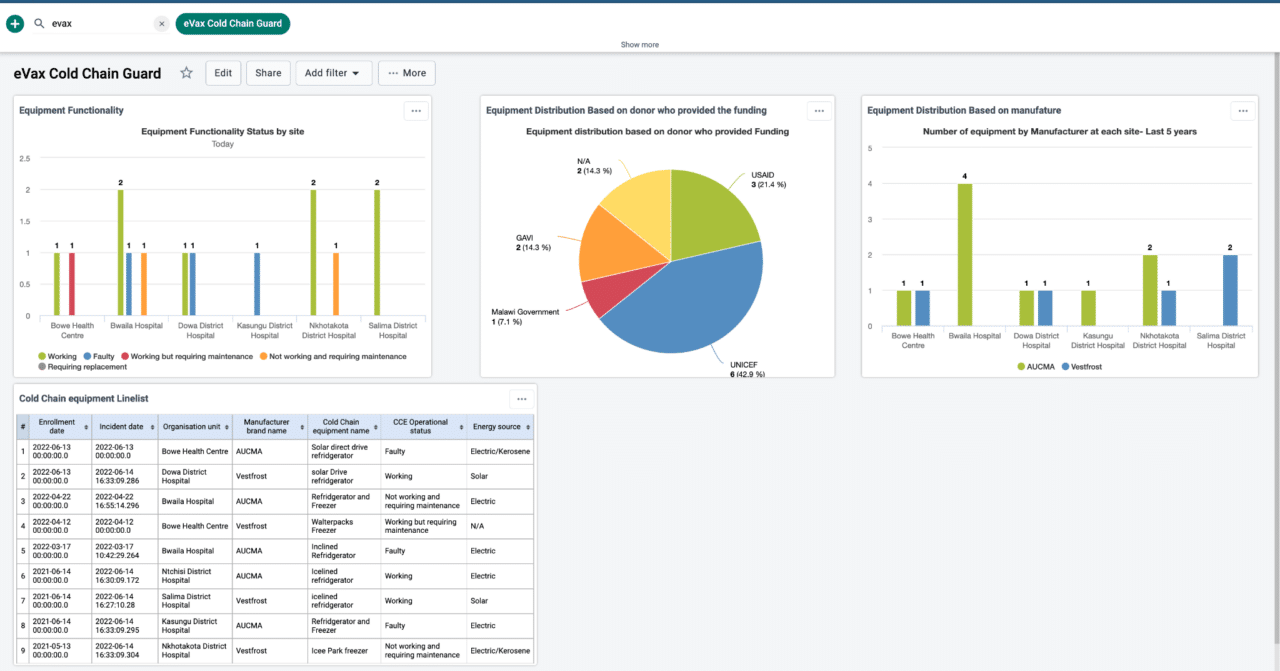

Custom dashboards provide partner transparency and support data-driven resource decisions

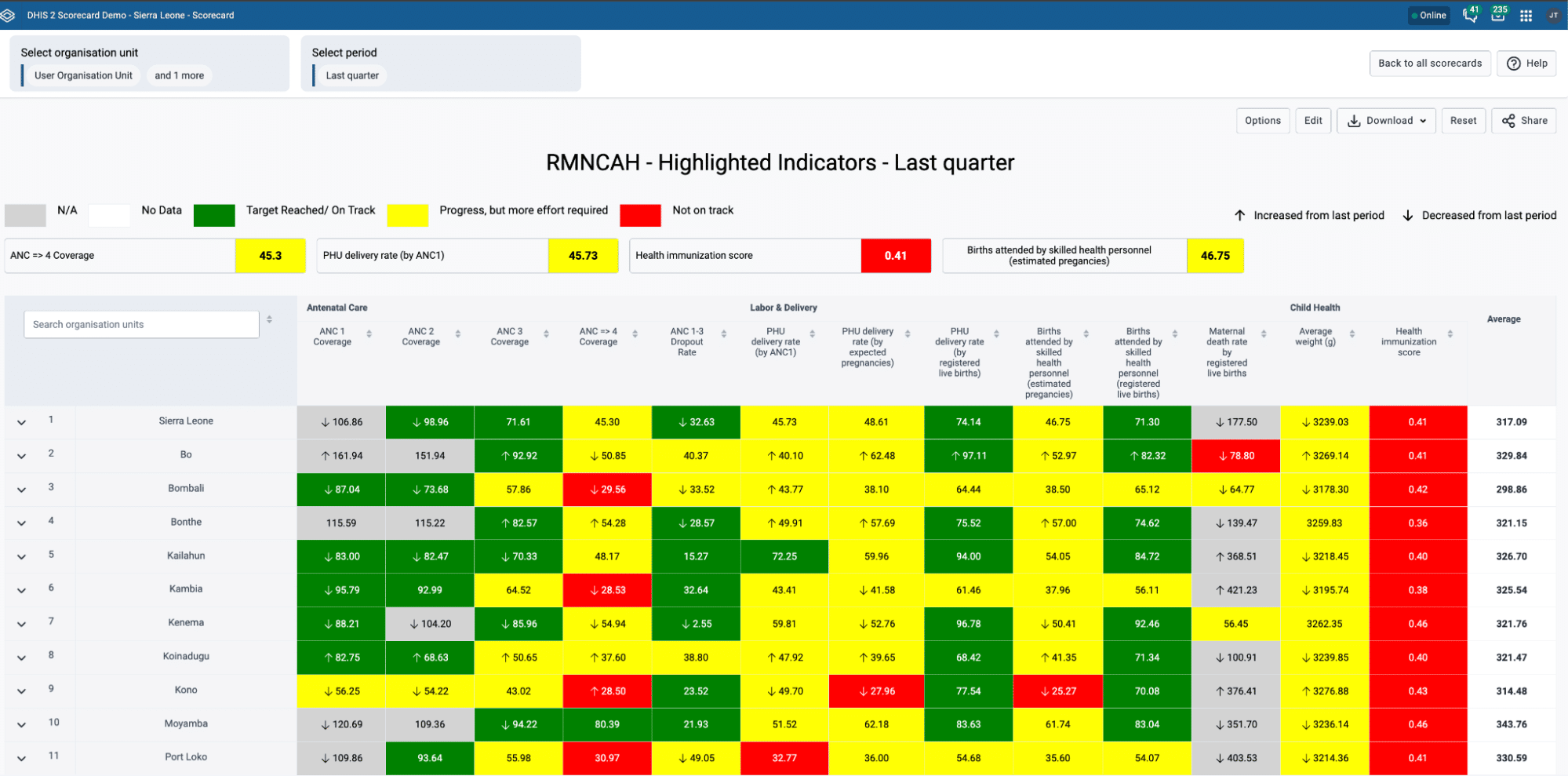

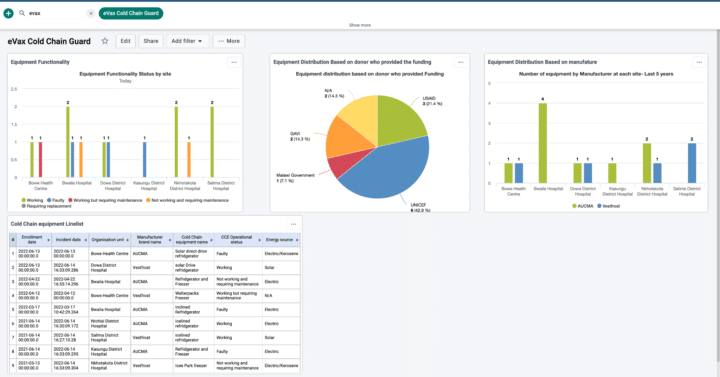

As part of the implementation of this CCE system, the Ministry’s Digital Health Division team created dashboards and line lists within eVax Cold Chain Guard to view and analyze various data—including operational status by district, available equipment by facility, types of equipment deployed, equipment with remote temperature monitoring devices, and more. These dashboards provide new functionality for cold chain managers, with real-time insights into equipment availability, maintenance requirements, and cold chain capacity versus actual stored volume.

“For each district, we are able to see how many pieces of equipment are functional, how many require maintenance, and how many are not functional,” Kamanga said. “If there’s a need to procure some equipment, we can easily see what kind of equipment to procure.” Because the dashboards also show the funding source for each piece of equipment, “we are able to show transparency and accountability in terms of the equipment that our donors and partners provide to the country,” Kamanga explained. This information can help donors such as Gavi, Unicef, and USAID monitor the effectiveness of their support to Malawi’s health system and prioritize areas for additional funding.

“Data inventory management is now kept in a simple and easily accessed [location] for analyzing and viewing, like CCE models, CCE volume, power usage, etc.” Anock Sinkhonde, Zonal Cold Chain Technical Assistant, South West Zone

Next steps: Expanding to other districts, integrating additional data sources, and onboarding more equipment

Since the initial stages of this CCE management digitization project, the Ministry has continued rolling out the eVax Cold Chain Guard system as part of a new, broader modernization roadmap to be implemented from 2025 to 2027. According to Kamanga, the roadmap supports the expansion of eVax Cold Chain Guard to other districts, as well as the integration of other types of data, including remote temperature monitoring data. “We are looking at carrying out orientations in those other districts, so that we can make sure all of the cold chain equipment is registered,” Kamanga said. “Some of the CCE items are equipped with remote temperature monitoring devices provided by Nexleaf, [and] the idea is to integrate that with the system we have created, so that it is automated.” Additionally, the Ministry hopes to transition the CCE monitoring system to reverse billing, and is considering expanding to include other types of equipment within the healthcare sector.

This article is based on a presentation by Blessings Kamanga at the DHIS2 2024 Annual Conference. Watch the recording on YouTube (begins at 24:26) and view the slides on Google Drive. Hear his perspectives on this project in the video below.