Deploying DHIS2 for eLMIS to improve Malaria stock management in Equatorial Guinea

The Bioko Island Malaria Elimination Project customized the WHO-DHIS2 logistics module to help prevent stock-outs, improve forecasting and strengthen program management

For over a decade, the Bioko Island Malaria Elimination Project (BIMEP) has collaborated with the Ministry of Health and Social Welfare of Equatorial Guinea to procure malaria commodities that are issued to public health facilities, including prevention materials, diagnostic testing supplies, and antimalarial treatments. The BIMEP has developed multiple iterations of Excel-based electronic logistics management information systems (eLMIS) to manage their central warehouse inventory, record stock distributions, and inform malaria commodity procurements. While these have been useful in supporting record keeping efforts, more complex analyses–such as forecasting consumption rates, triangulating stock and health services data, and estimating procurement needs–were challenging.

As budgets for Malaria-related activities continued to decline, and global supply chains became increasingly strained, the BIMEP determined that an enhanced eLMIS was essential to ensure that an adequate stock of Malaria commodities were available to protect vulnerable populations from one of the most frequent illnesses in this small, central African nation. The project was already using DHIS2 to collect health-related data, and decided to expand their DHIS2 system to integrate it with a suite of DHIS2 logistics modules for malaria, which would empower the team to better forecast procurement requirements, respond to facility needs, and ensure adequate stock and management of malaria commodities at all levels of the public health system.

The BIMEP’s new, DHIS2-based eLMIS system has already made an impact on Malaria programs on Bioko Island, helping prevent stock-outs and ensure adequate stock-on-hand at the central warehouse and all public health facilities, uncovering gaps in internal and external reporting mechanisms and potential sources of stock leakage, and increasing accountability and transparency.

Transitioning from Excel to DHIS2 to improve data quality and support forecasting, triangulation and procurement estimates

Commodities procured by the BIMEP are inventoried in a central warehouse by BIMEP staff, who also manage their distributions to public health facilities. The eLMIS systems developed by the BIMEP using Excel had several limitations that affected the project’s ability to effectively manage Malaria stocks. Being based on Excel (without a central database, user management or validation workflow) these systems were prone to data entry error and data loss, thereby compromising their reliability. Also, any complex analyses using eLMIS data, such as forecasting, were performed manually and often resulted in delays in reporting to headquarters. This contributed to stock-outs within the central warehouse, especially during the COVID-19 pandemic when global supply chains were strained.

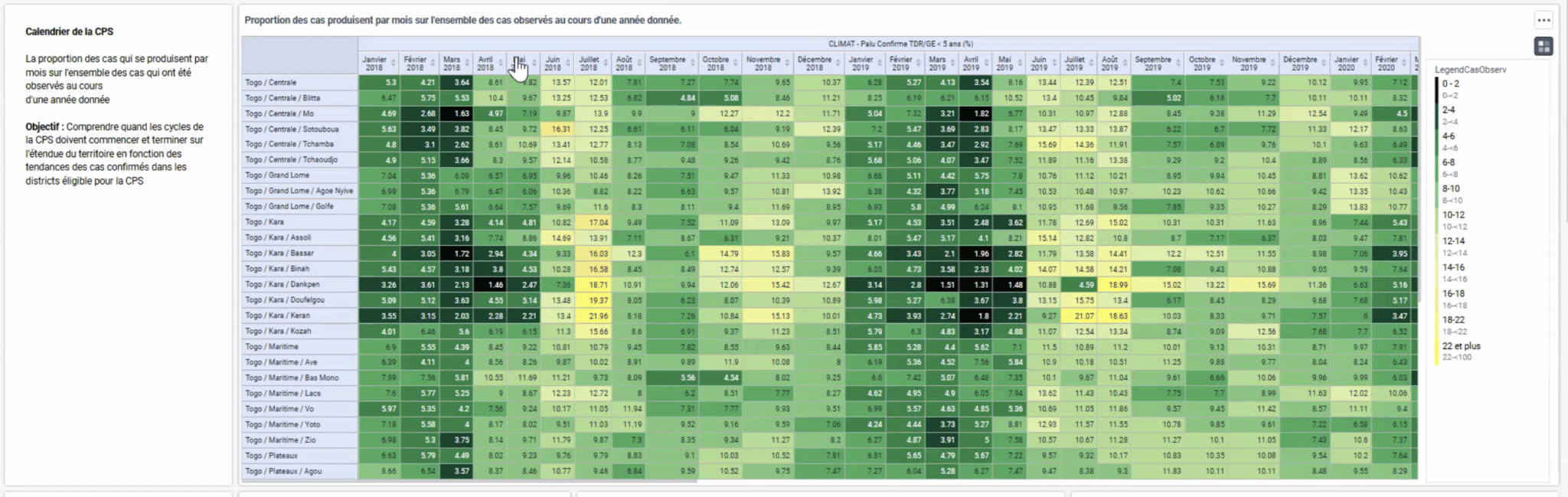

Already equipped with a robust DHIS2 platform to collect health services data, improve health worker quality of care, and conduct weekly malaria surveillance, the BIMEP saw an opportunity to leverage their existing DHIS2 instance for Malaria logistics management to help address the issues with their current eLMIS and support improved stock management. The objectives of this effort were to configure core logistics indicators for each commodity as well as predictors to estimate current stock-on-hand and estimated months of stock-on-hand at central warehouse given consumption rates to forecast procurement needs, and to triangulate stock data with health services data to better understand stock performance and losses (stock discarded and stock discrepancies).

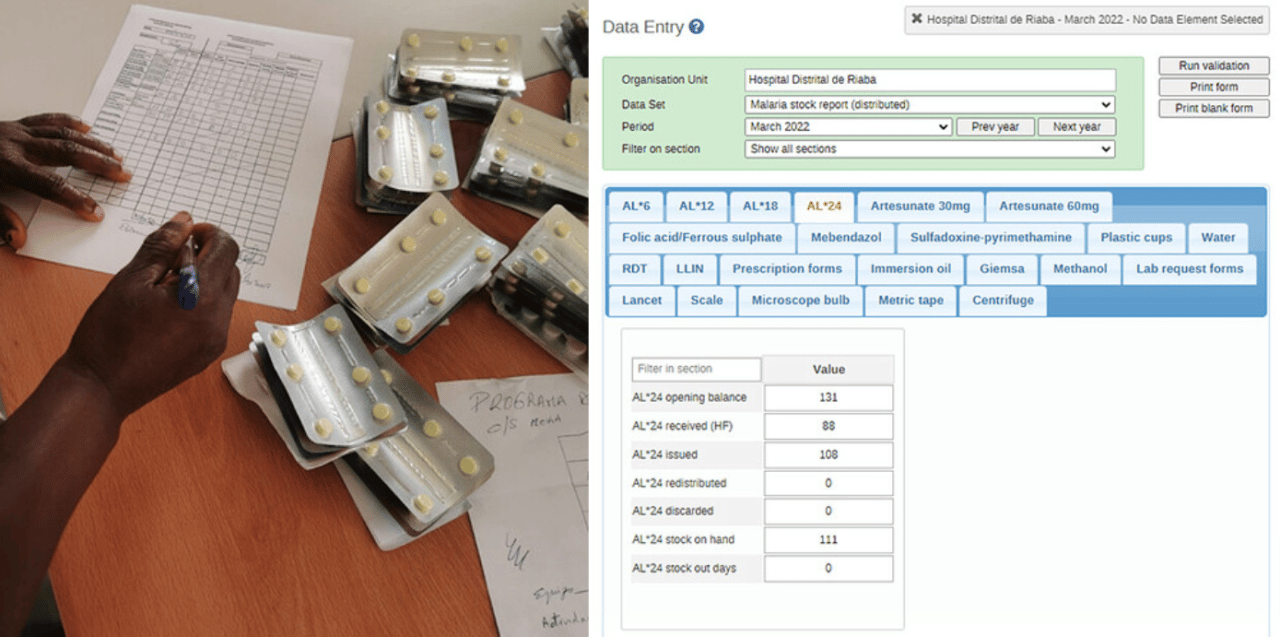

Leveraging the development of the WHO common logistics data framework, the Aggregate DHIS2 metadata package for Malaria Logistics was integrated into the existing DHIS2 instance and adapted to meet country needs. The BIMEP staff use the malaria logistics module to track malaria commodity distribution data from the central warehouse to the health facility level. The package was adapted to include additional commodities for individual malaria treatment/prevention schemes as well as laboratory supplies for malaria diagnostics. Additional indicators and visualizations were configured to support programmatic efforts.

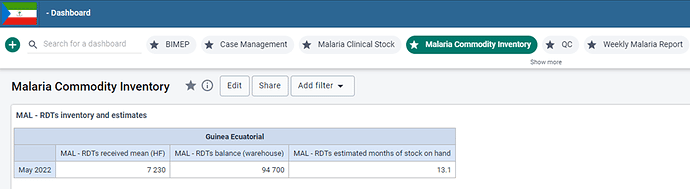

A DHIS2 Event program was also configured to model quantities of each malaria commodity received into the central warehouse, along with its expiration date and lot ID. DHIS2 notifications were configured to alert staff when commodities in the central warehouse are nearing expiration date. In addition, DHIS2 predictors were configured to create running totals of both stock received into and stock distributed from the central warehouse in order to generate indicators for estimated stock-on-hand and estimated months of stock-on-hand for each commodity, which are presented in a dashboard for managing stock procurements. Notifications also alert managers to begin procurement procedures when commodity stock-on-hand reaches a critical threshold given predicted consumption rates.

Paper-based forms are carried into the field for collecting data on commodity distributions, which are subsequently entered using the web-based DHIS2 data entry app; however, the transition to using the DHIS2 Android Capture app is in progress. The web-based DHIS2 capture app is used at the central warehouse to enter event data for stock received upon procurement.

Making an impact on Malaria project management with accurate, timely data to improve analysis and drive decision making

One of the main benefits of the DHIS2 eLMIS is the automatically forecasted indicators that estimate stock-on-hand and months of stock-on-hand at the central warehouse. The previous eLMIS system did not offer features for forecasting stock needs given commodity consumption rates. Consequently, there were multiple occasions when the central warehouse experienced stock-outs due to delays associated with health services and distribution data needing to be manually compiled, and procurement indicators needing to be manually calculated. By the time these calculations had been reported to headquarters for procurement, it was already too late, especially during the COVID-19 pandemic, when the global supply chain was already strained. The indicators and alerts configured in DHIS2 rapidly provided staff with the data they needed for decision making through stock procurement forecasting, which helped to ensure adequate stock-on-hand at the central warehouse and at public health facilities.

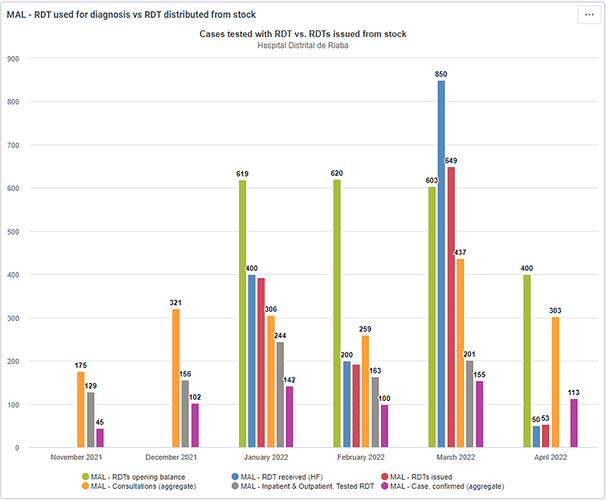

An equally important benefit of the eLMIS is that it enables the team to easily triangulate stock distribution data with health services data. These indicator visualizations help the team to better understand stock performance and losses while also providing them with data to inform health facility managers on how they may improve stock management within their respective facility. Within the first month of implementing the eLMIS in DHIS2, the team immediately noticed data discrepancies between the multiple reporting mechanisms in DHIS2, namely stock distribution reports, weekly malaria reports, and detailed patient registries. For example, in one District Hospital, the number of RDTs issued to patients was reported to be greater than the number of tests performed according to digitized patient registries. Furthermore, the number of RDTs issued to patients was greater than the total number of consultations reported through the weekly malaria surveillance module during that period.

Such visualizations, which were previously unattainable within a timely manner, provide the team with easily understandable evidence that they need to support investigations and react quickly. By triangulating stock and health services data, the teams discovered gaps in both internal and external reporting mechanisms, as well as potential sources of stock leakage, which could then be discussed in strategic planning meetings with key stakeholders. In addition, the data empowered the BIMEP team to more closely monitor their own internal workflows, thereby increasing accountability and transparency.

Challenges and opportunities for further improvement of logistics management with DHIS2

Despite significant achievements, the BIMEP team faced a number of challenges as they implemented the eLMIS in DHIS2. Due to the unavailability of certain malaria treatment schemes from pharmaceutical providers, many of the treatments in stock at the central warehouse needed to be repackaged for distribution in order to avoid stock-outs at health facilities. Fortunately, DHIS2 provided flexible means of modeling these changes, and novel indicators enabled the team to continue monitoring their inventory without any substantial complications. Additionally, as this cost-effective eLMIS was not intended to replace a fit-for-purpose transactional eLMIS, the system is limited in its ability to estimate inventory and track commodity by lot numbers throughout the public health system. Nevertheless, the module created to record stock received into the warehouse has been configured to notify the team when commodities are nearing their expiration date.

Although most of the challenges have been met with solutions made possible by the flexibility of DHIS2, the biggest challenge remains: instilling a data-driven culture within the drug distribution team to ensure adequate management of malaria commodities. While the tools are available in the eLMIS, the team is still learning how to use the data for decision making. Online DHIS2 Academies offered through the HISP network and BAO Systems have strengthened the staff’s technical skills; however, conveying the results generated in the system to the various stakeholders is an equally important process that requires a different set of skills and training. The BIMEP has a wealth of experience working with information systems, and these experiences have taught them that creating a culture of data-use is an iterative process in which progress is made through continuous systems refinement and feedback to all stakeholders.

The BIMEP team is looking at novel ways that they can further leverage their DHIS2 to model other activities and commodities in their inventory while continuously strengthening their efforts in eliminating malaria on Bioko Island.

This article was adapted from a report by Jordan Michael Smith. Learn more and share questions and comments about this project on the DHIS2 Community of Practice.